Diversity grows on the periphery: With FormDress, Agathon further expands the range of applications of its Evo Combi and Evo Penta grinding machines. This makes them even more versatile. Using FormDress, makes it possible to grind complex contours into the surface of the workpiece with the peripheral rim.

FormDress is Agathon’s newest innovation. It allows the peripheral rim to be shaped in such a way that even complex contours can be ground. PeriGrind offers the user the option of using the peripheral rim in addition to the front rim in one clamping operation. Or to put it in practical terms: the user decides whether to use the front or peripheral rim alone or in combination. This allows him to expand the process engineering possibilities with minimal effort, to include the peripheral rim options without having to renounce to the advantages of the highly productive front rim.

These process possibilities result, among other things, from the fact that the peripheral rim does not touch the workpiece over its entire surface but on one line only. Geometries which cannot be obtained with the flat front rim can be produced this way. The concave shapes of modular inserts and their chamfers can be mentioned as an example.

The machine has to be retrofitted on the hardware side with a dressing device for the peripheral rim and the corresponding software integrated on the program side, in order to benefit from the possibilities offered by PeriGrind. Costs for both are low and the training expenses for the machine operators are also insignificant. The programming syntax has been consistently extended for grinding with the peripheral rim. Anyone who has already operated an Agathon machine will therefore not be confronted with anything completely new. In addition the dressing control for the peripheral rim is explicitly activated or interval-controlled, which ensures stable production. PeriGrind offers also a measurement option that is performed with the existing measuring probe. It compensates in a transparent way the fact that the rim thickness of the peripheral rim decreases with use.

FormDress – Complex contours with the peripheral rim

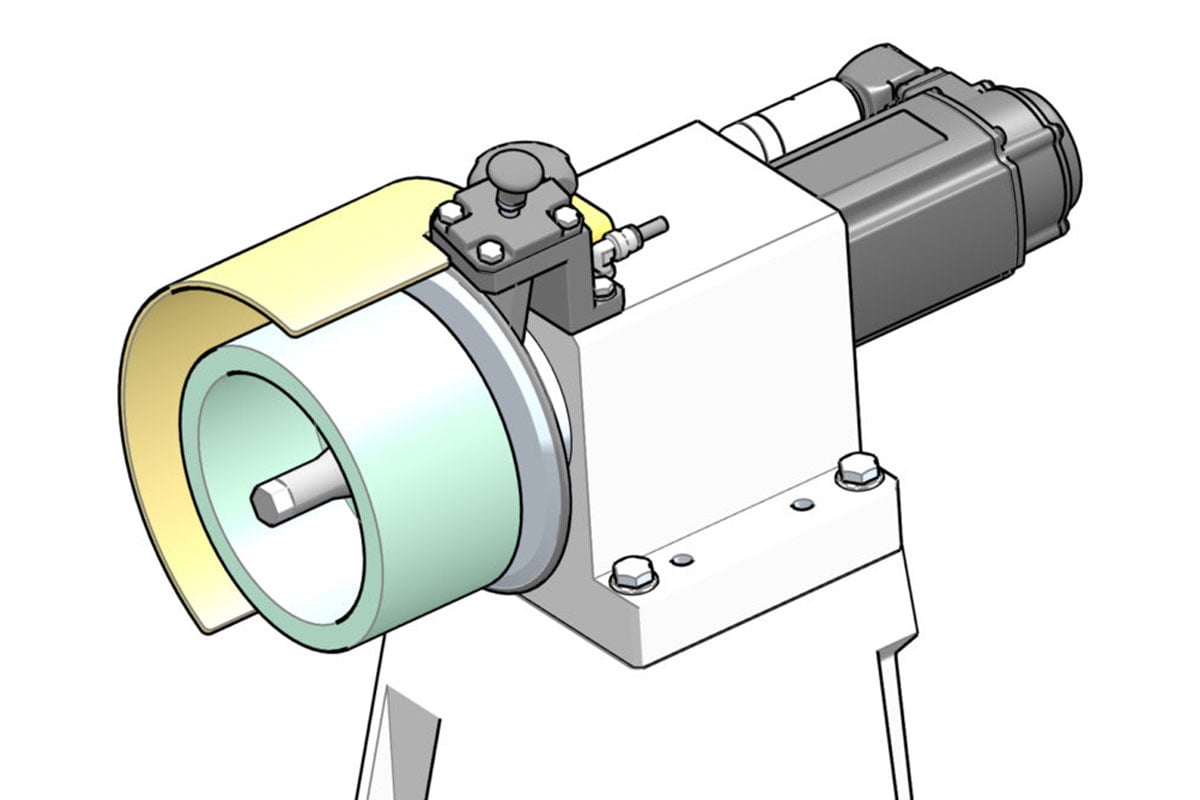

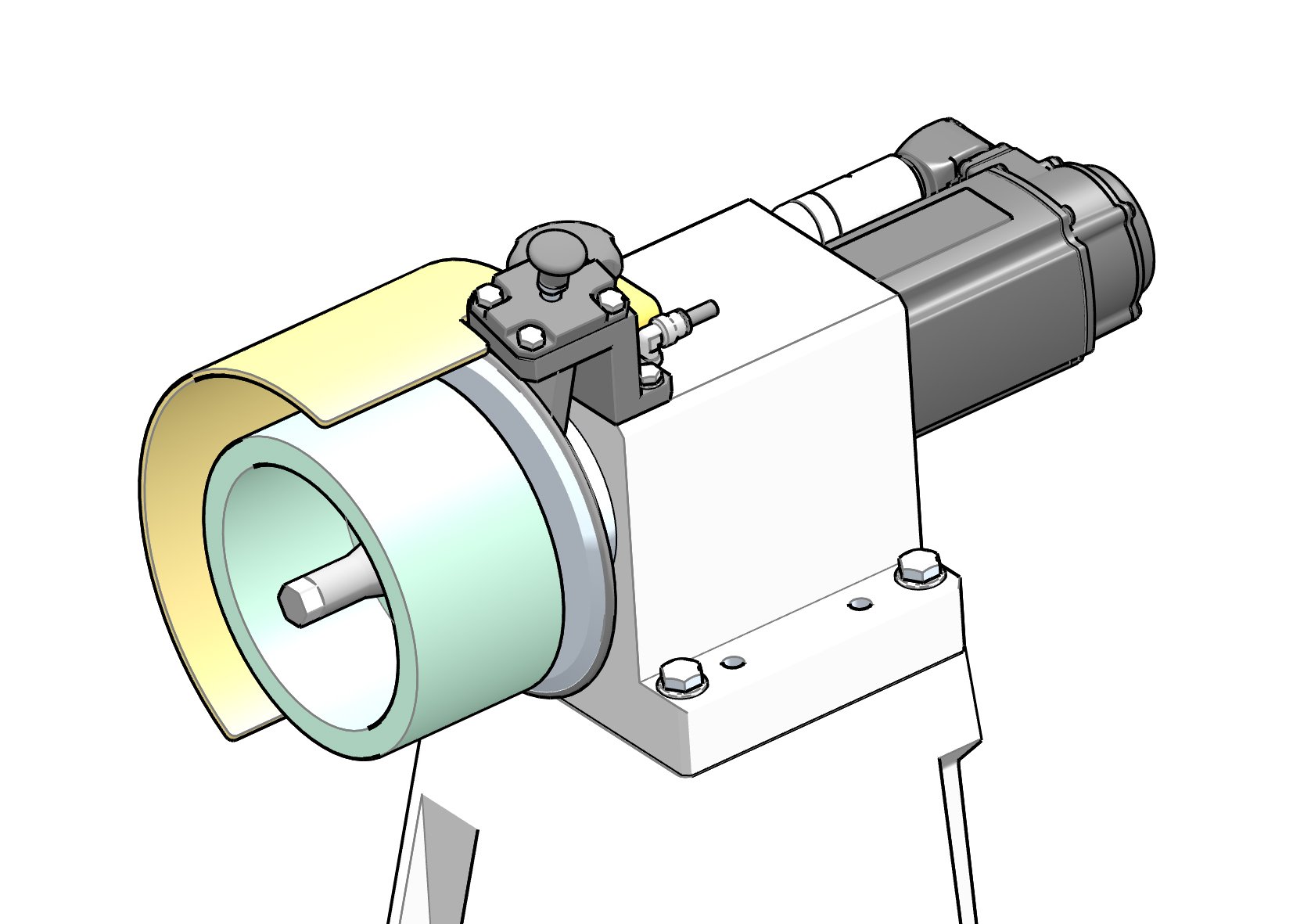

With FormDress, the user extends the already existing possibilities of PeriGrind by the processing of complex contours. What does this mean? For example let’s take an indexable insert which edge is to be provided with a groove that serves as an interface to a clamping system (Figure 1). This is not possible with a flat surface, meaning that the peripheral surface must be shaped accordingly. This is done with a dressing device specially designed for FormDress. The respective diamond wheel of the device makes it possible to profile the peripheral rim in such a way that the indexable insert in our example can be machined. Further application examples for FormDress can be found in the machining or production of grooving inserts.

Agathon CTO Dr. Stephan Scholze explains: «With FormDress the application possibilities of our grinding machines can be expanded even further, thus making the user more flexible once again». Furthermore so Scholze: «The customer receives even more value-for-money. With PeriGrind, the user can combine front and peripheral rims in one clamping operation, enabling him to shorten the process chain by at least one process step up to the finished workpiece. And this in turn increases the productivity of the machine».

In addition, it should be mentioned that the respective form is created by using existing, highly rigid and high-precision axis systems and by moving the X and Y axes interpolated. The advantages of these are not only a compact design and maximum precision at a reasonable price, but also an easily upgradeable machine. Agathon offers FormDress for the Evo Combi and Evo Penta machine models.

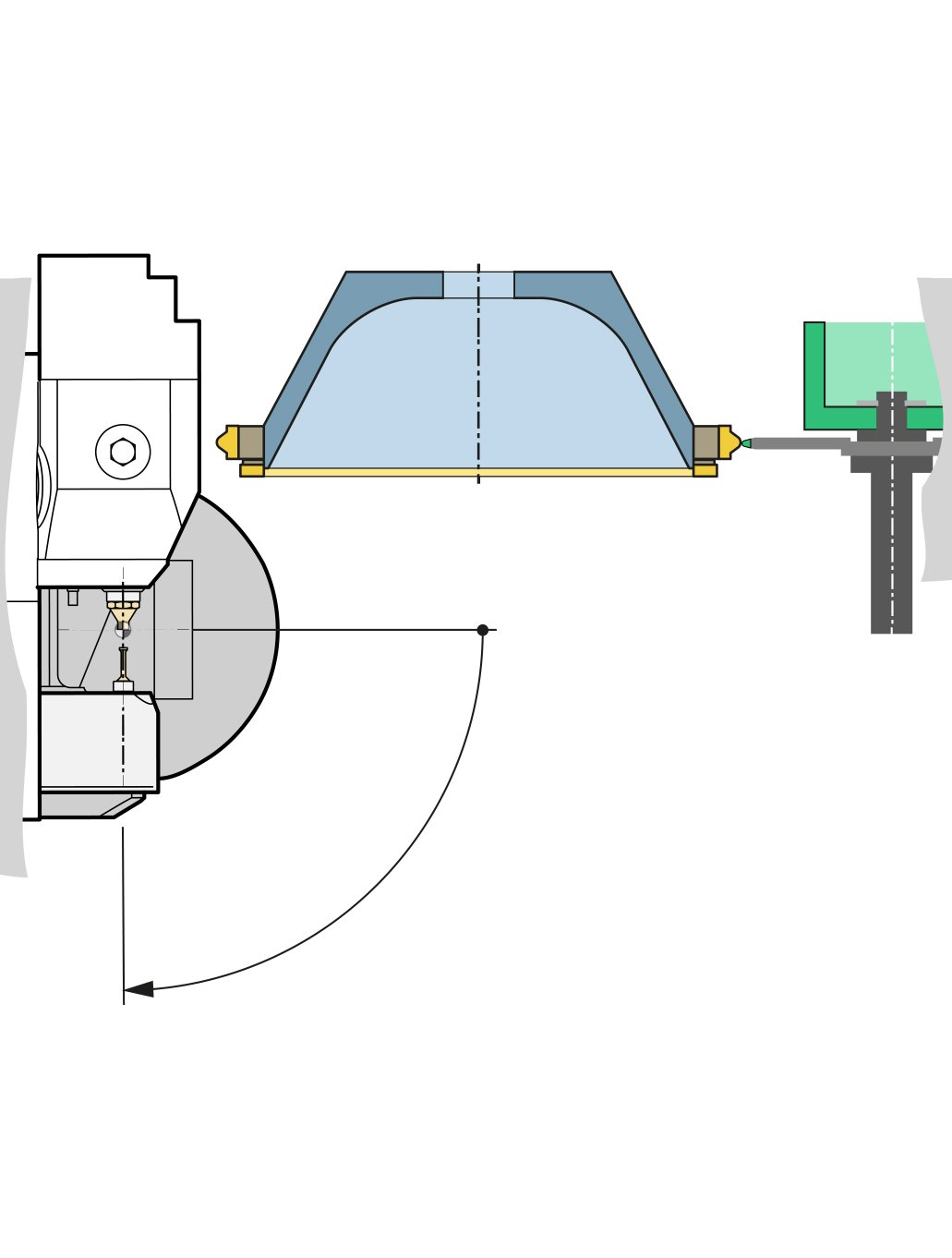

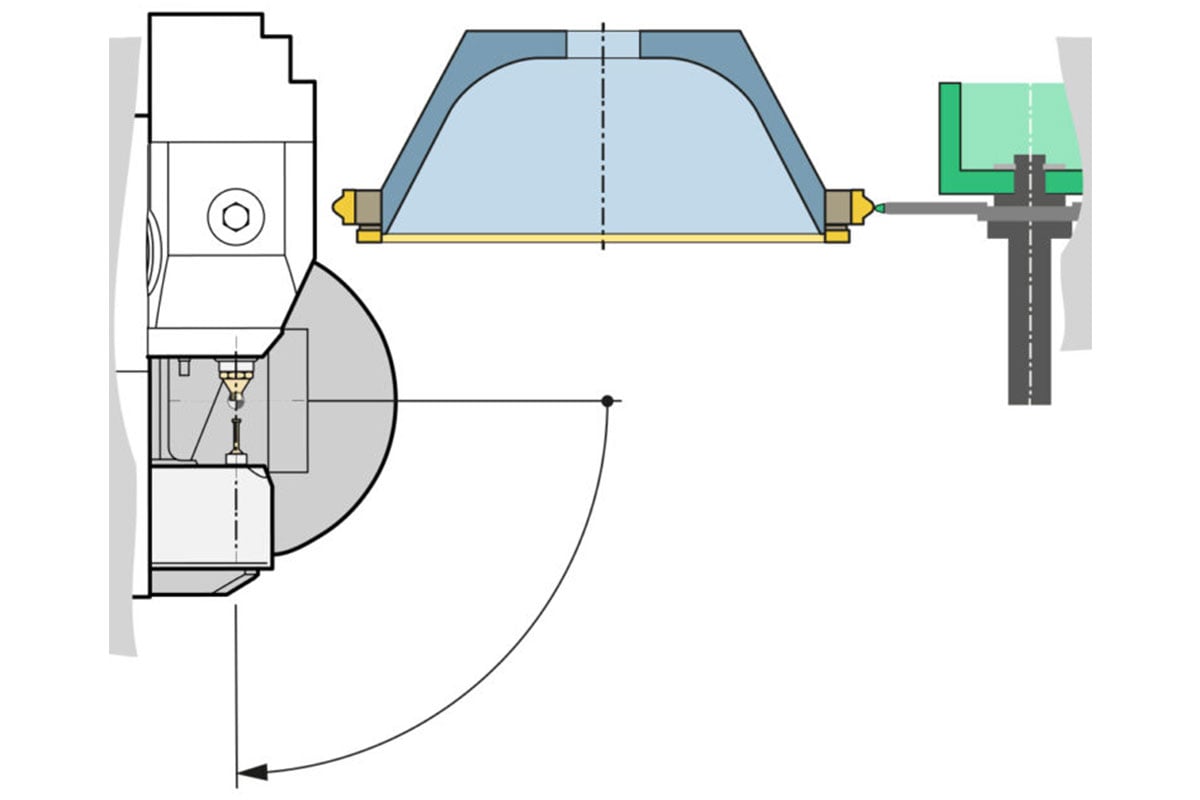

Schematic representation of the FormDress dressing device. This can be integrated into the Evo Penta and Evo Combi machine models.

Schematic representation of the FormDress dressing process.