| Datapool |

Professionelle SQL-Datenbank für die zentrale Speicherung, Organisation und Verteilung von Werkstückdaten |

|

| PeriGrind |

Peripherieschleifbelag mit erweiterter Programmiersyntax (PeriGrind) |

|

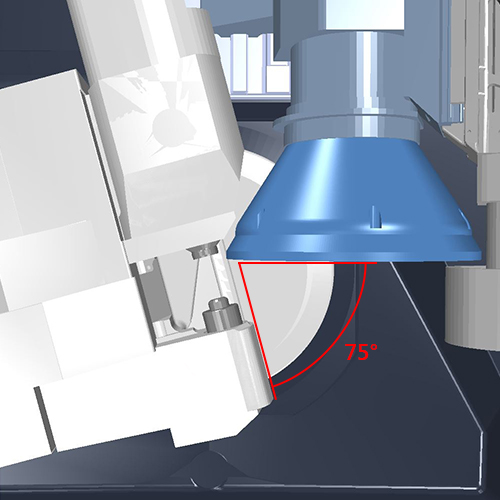

| Fasenschleifen für Leo Peri |

Hochproduktives Fasenschleifen von Schutzfasen von mehr als 15° |

|

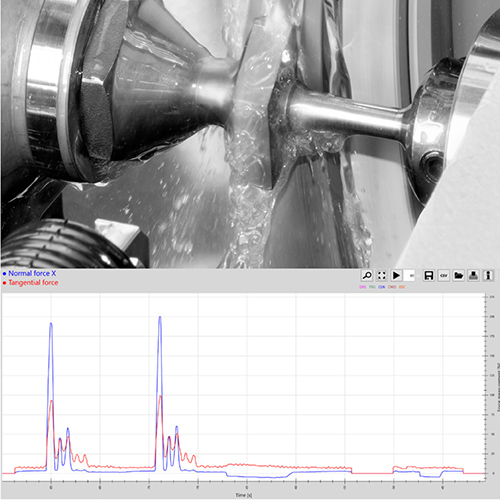

| Kraftmessung |

2D-Kraftmessungssystem für Normal- und Tangentialkraft zur Prozessdefinition, Optimierung und Kontrolle |

|

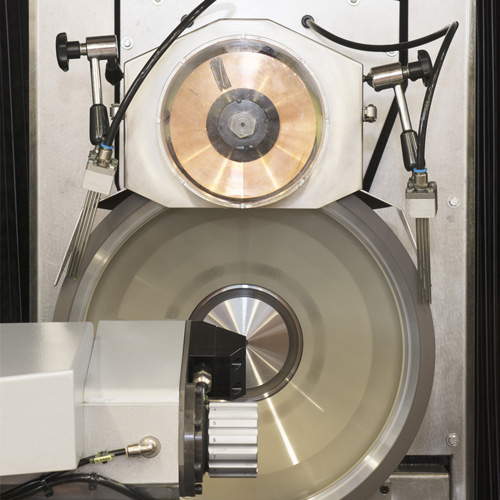

| B1-Teile umspannen | Mehrfachspannen |

Dom Plus: Schleifen einer zweiten Fase

Evo: Schleifen eines Werkstücks in mehreren Aufspannungen |

|

| Adaptiver Vorschub |

Ergänzend zum konstanten Vorschub wird hier die Schleifkraft vorgegeben |

|

| Programmierplatz |

Offline-Programmierumgebung am PC-Arbeitsplatz mit identischer Bedienoberfläche wie an der Maschine |

|

| AGS 3D-Simulation |

Interaktive 3D Schleifsimulation zur Erstellung vollständiger Schleifprogramme |

|

| Erweiterte 3D-Simulation |

Erweiterte 3D-Bearbeitungssimulation bietet deutliche Verbesserungen bei der Visualisierung und bildet u.a. den gesamten Schleifbereich ab |

|

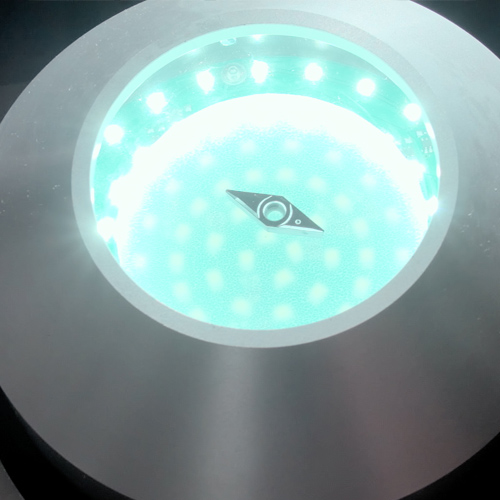

| AGP-Iso |

Grafische Erstellung von Schleifprogrammen für ISO-Wendeschneidplatten |

|

| FRP - Free Reference Plane |

Programmierbefehl, mit dem das gesamte Programmier-Koordinatensystem FRP beliebig gesetzt werden kann |

|

| Edge Grinding |

Programmierbefehl, mit dem ein Kurvenzug mit der Schleifscheibenkante ECH geschliffen werden kann |

|

| Spline |

Programmierbefehl, mit dem ein allgemeiner Kurvenzug SPLINE mittels vorgegebener Punkte geschliffen werden kann |

|