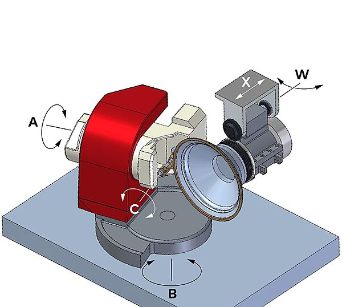

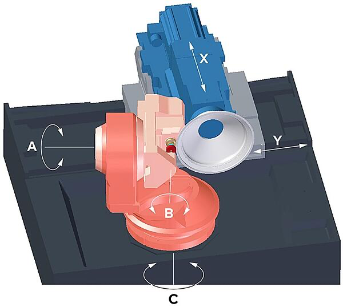

You can carry on using your preferred process technologies: productive transverse side surface grinding, universal pin clamping, in-process dressing, four-axis and five-axis kinematics, integrated thickness measurement, 3D measuring probe and much more. You benefit from short set-up times for the robot handling and the grinding process. What’s more, you have a wide range of new possibilities: inscribed circle measurement for process correction, grinding with cup wheel and periphery rim, 2D process force measurement, adaptive infeed, PowerGrind, Smart Connectivity and many other options. Your maintenance outlay is reduced thanks to state-of-the-art direct drives and durable sealing solutions, for instance in the area of workpiece clamping. Agathon works in close collaboration with renowned grinding rim manufacturers. Our application engineers are experienced and are not bound to any particular rim manufacturer. We can therefore establish the best solutions for you.