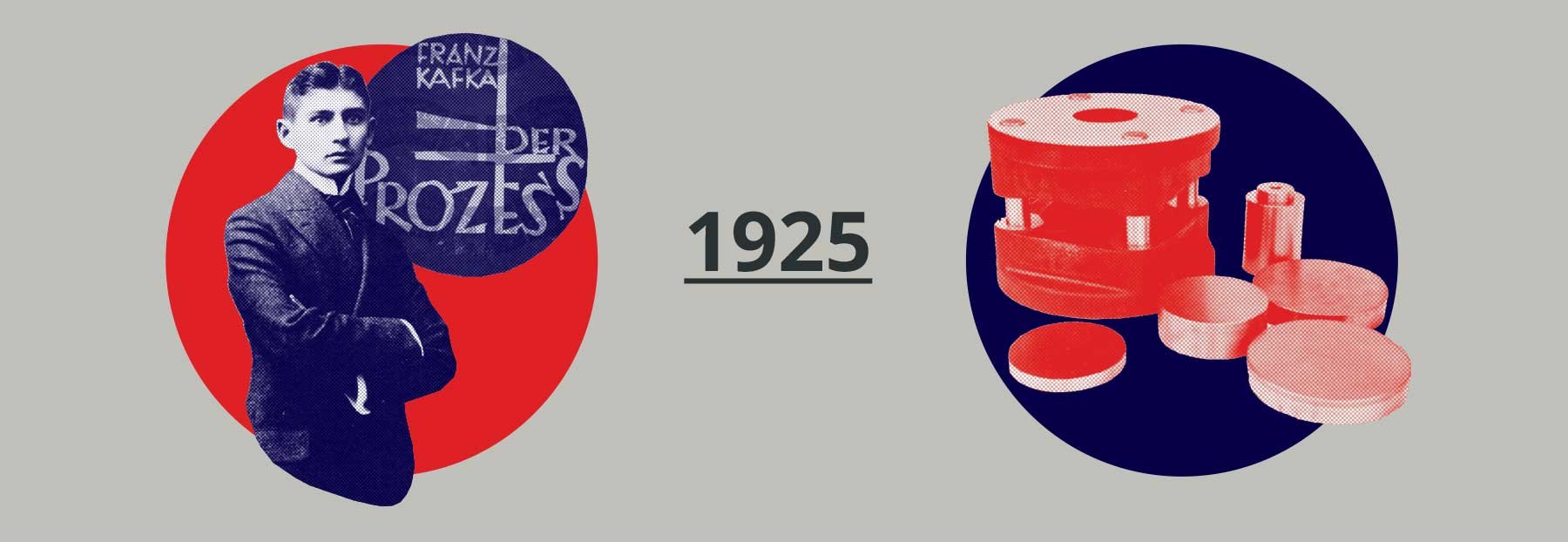

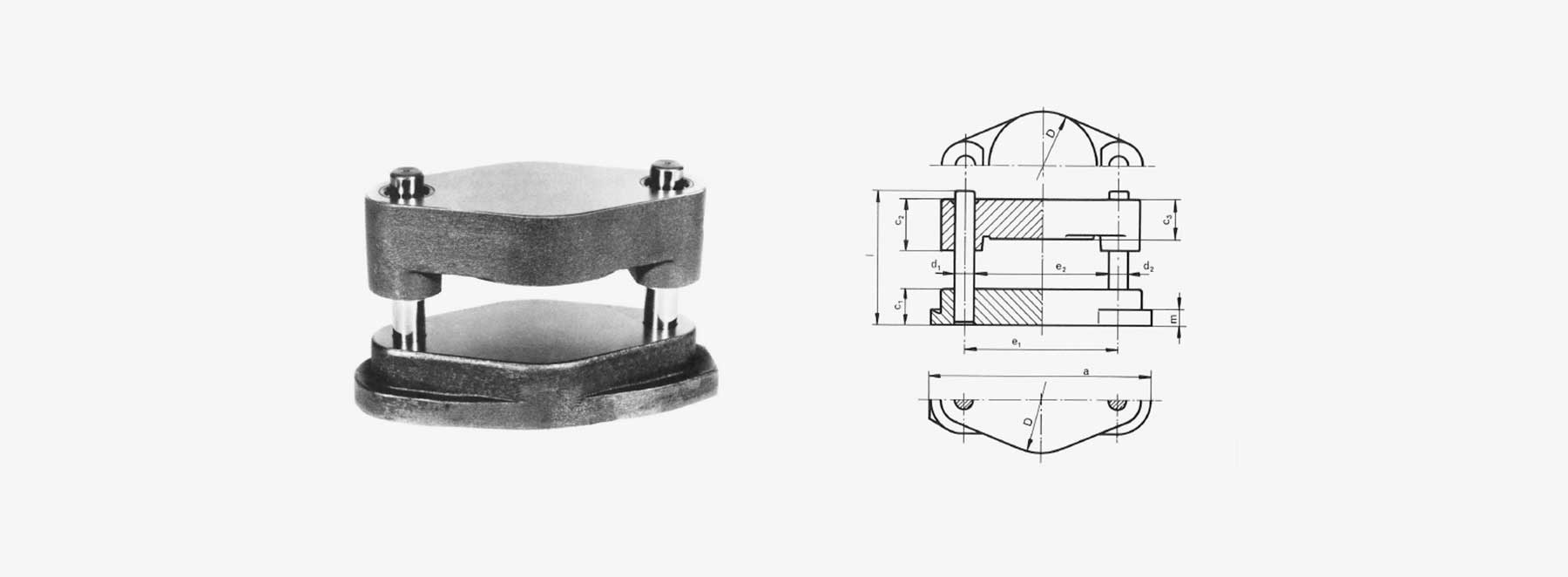

As from 1925, Agathon supplies the watch industry with die sets equipped with sliding guides. The region along the Jura Arc from Basel via Solothurn to Geneva is still known today as the «Watch Valley».

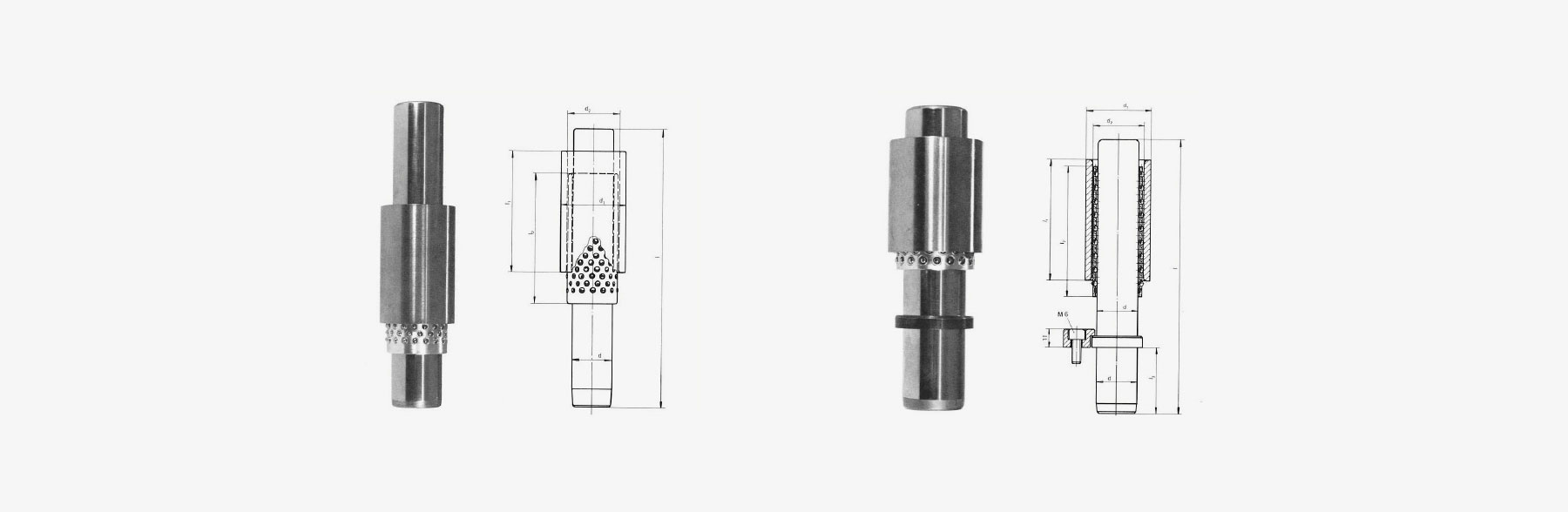

During his studies in England, Hugo Pfluger recognized the potential of rolling elements in the use of guide systems in toolmaking. Agathon was the first company to offer ball guides for toolmaking, thus meeting the demand for higher precision.

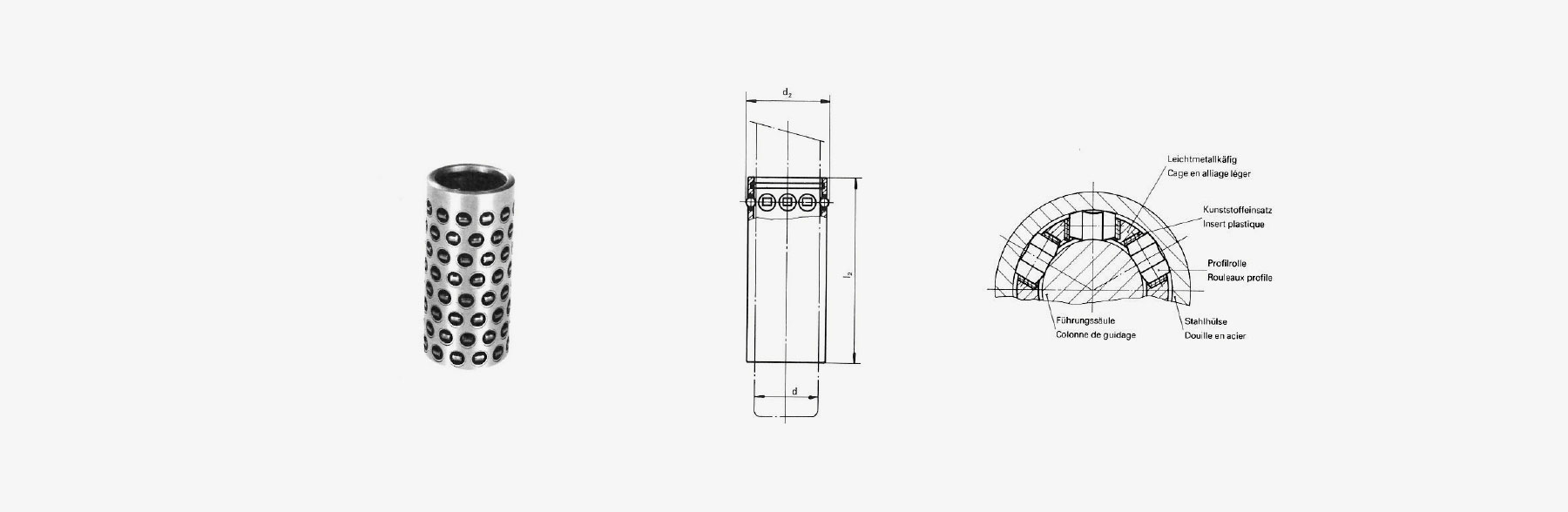

For punching very thin or hard materials, even more rigid and robust guides are required. Roller guides with profile rollers are therefore launched on the market.

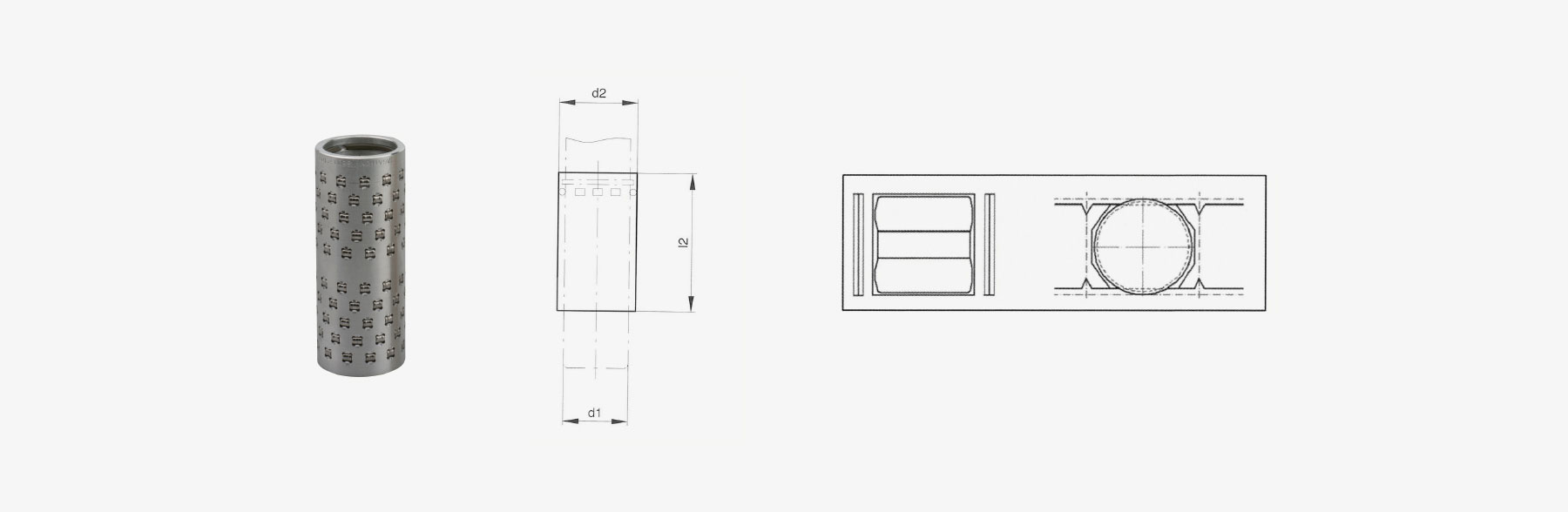

Tools for high-speed presses require corresponding roller guides. For this purpose, roller guides with the patented Agathon roller are launched on the market.

With the conversion of the guide elements to the ISO/DIN standard and in order to achieve even longer service lives, modifications were made to the products: For example, the receiving pockets on roller cages, a new caulking on ball cages and the handling on the movable cage retaining system have been optimized.

With the patented Agathon centering system, an extremely successful alternative to conventional centering in mold making is introduced on the market. New products are constantly added to the range.

The Mini Fine Centering enables highly flexible tool concepts in punching tooling and mold construction and thus makes it the new star in variant production. In precision automation also, the Mini Fine Centering opens up previously closed doors, for example when positioning gripper tools.