Agathon Centering in Mold Making – even when it gets hot, it stays cool! Backlash-free and rolling guide systems are increasingly pushing back the low-cost, unprecise conventional cubic flat centering in injection mold construction. But do they retain their high precision even in the case of heat differences inside the mold? And how is the heat distributed over the mold? Agathon provides the answers.

« I believe in the horse, the automobile is a temporary phenomenon. » Today, we smile at this spectacular misjudgement of the German Kaiser Wilhelm II – and at the same time use cubic flat centering systems far too often in mold construction. Such flat centering may well be appropriate for some applications, but whether such centering devices, which are not backlash-free, should be installed in a costly molding tool that has to work with high precision, must certainly be doubted. In practice, the result of this work inevitably leads to mold elements, for example inserts, wearing out far too quickly, which means high costs. Buyers who have had to purchase the same customer-specific inserts repeatedly can tell us about it.

An increasing number of mold manufacturers are investing in backlash-free centering systems to ensure that the two parts of the mold with its possibly numerous core inserts, are brought together with high precision. The demand for Agathon’s backlash-free, preloaded, anti-friction guides is also increasing constantly, confirms Stefan Nobs, Technical Manager Standard Parts. Longer service life and rigidity are further advantages of preloaded anti-friction guides. «This results in extremely high precision and massive cost savings», says Nobs. Because the mold inserts are centered with high precision, wear is greatly reduced. Cores and inserts must rarely be replaced. And because such centering generates practically no abrasion, it is also an ideal choice for cleanroom applications.

The carriage drivers of the late 19th century had at least one good and serious argument for the horse and against the automobile: They rightly doubted that the pharmacies, which were the only ones to sell petrol at that time, could supply enough fuel for a larger fleet of cars. Practice has shown that this challenge was much smaller than originally thought. In the end, the horse was left behind. And even against the use of backlash-free centering systems such as the Agathon centering system, a reservation is often formulated. It is feared that a different temperature of the mold halves will lead to a position offset. Especially in the high-end segment, different tempering is often unavoidable and necessary for a safe process. Losses in the performance of the anti-friction guides are suspected due to the temperature jump between the ejector side and the injection side. The inhomogeneous heat influence of nozzle heating or local cooling also causes concerns.

Heat is distributed evenly through the entire mold

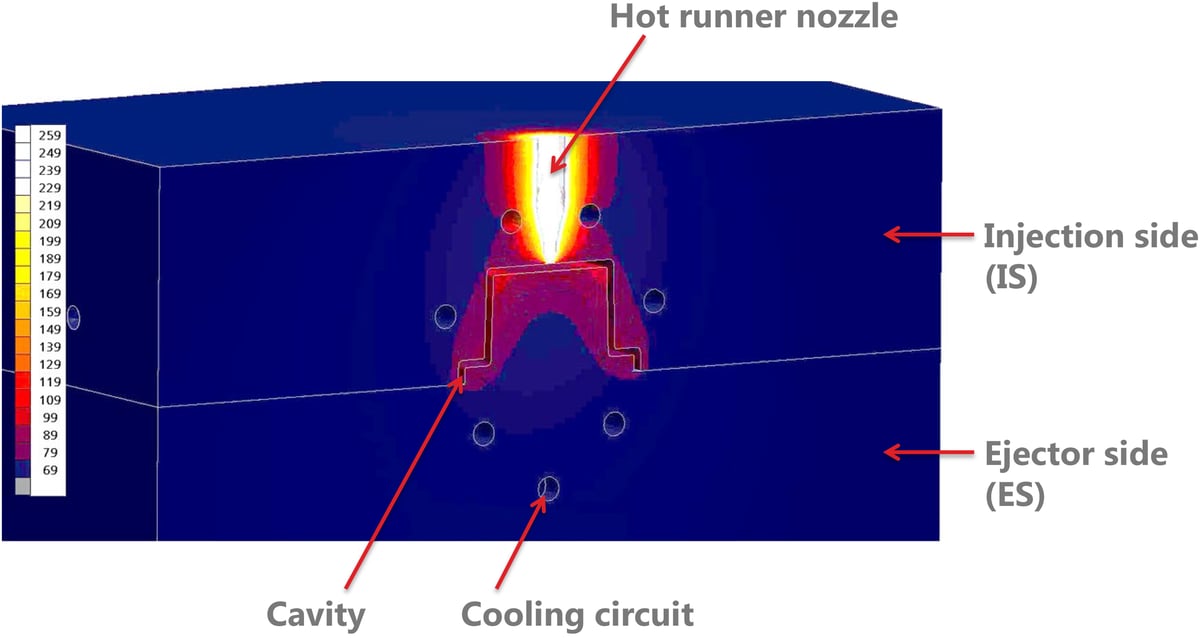

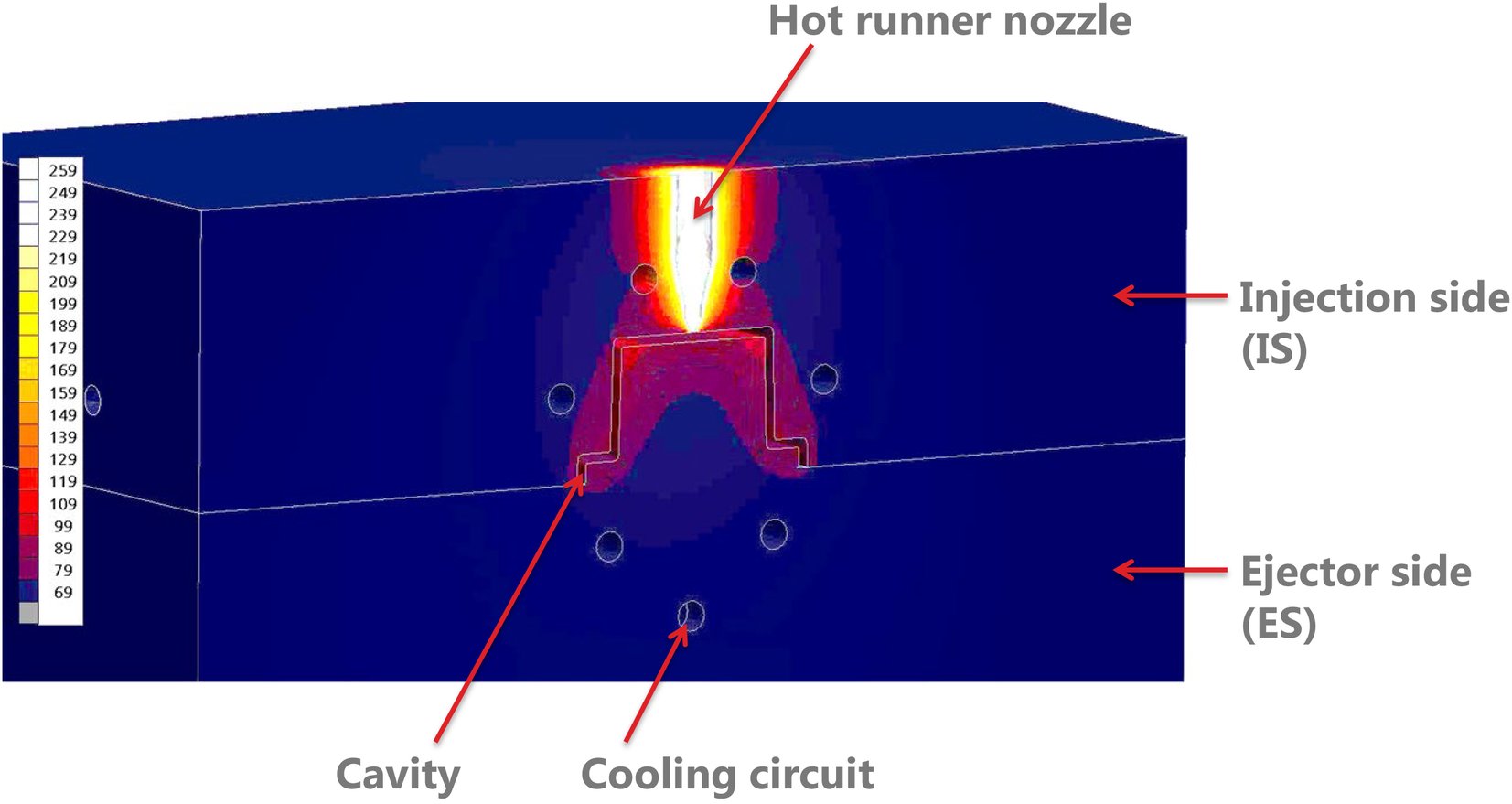

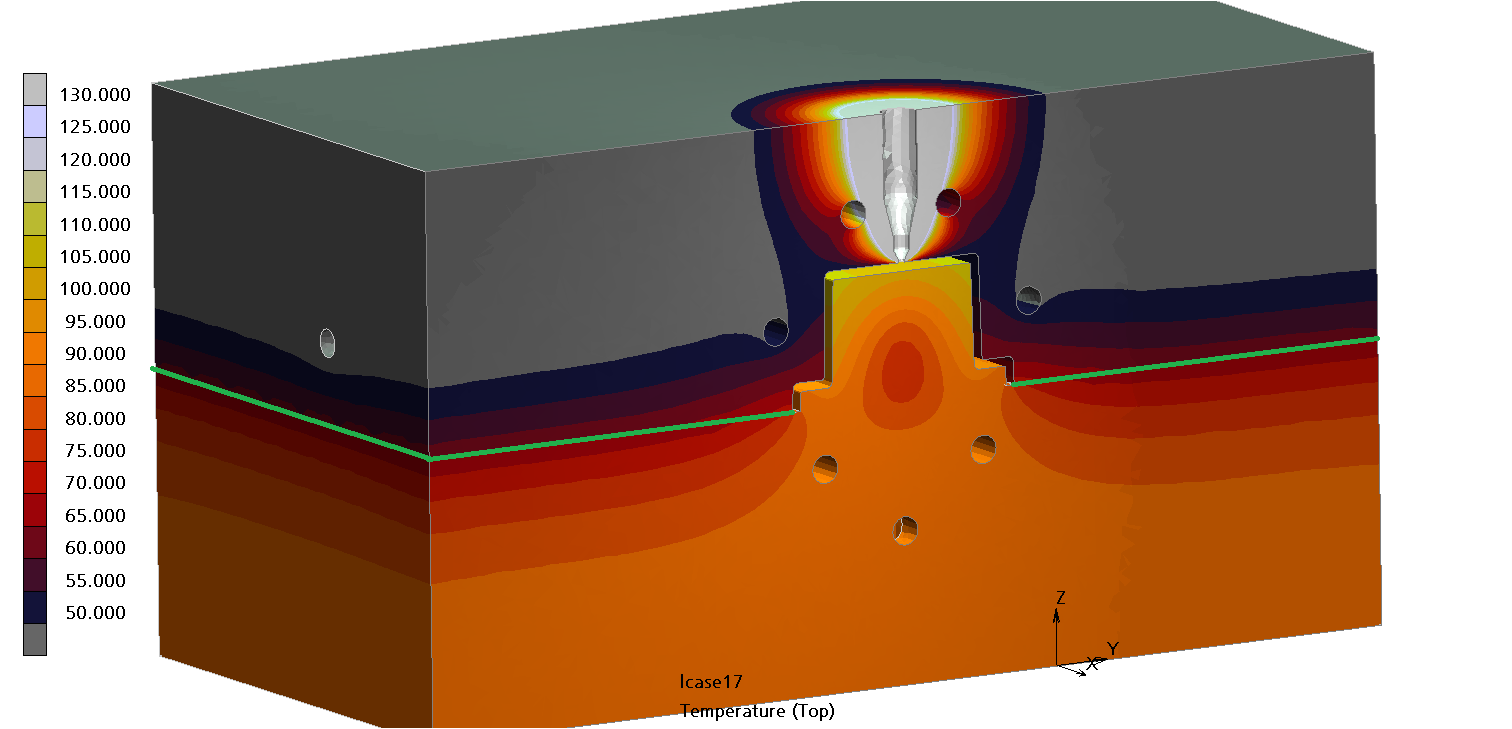

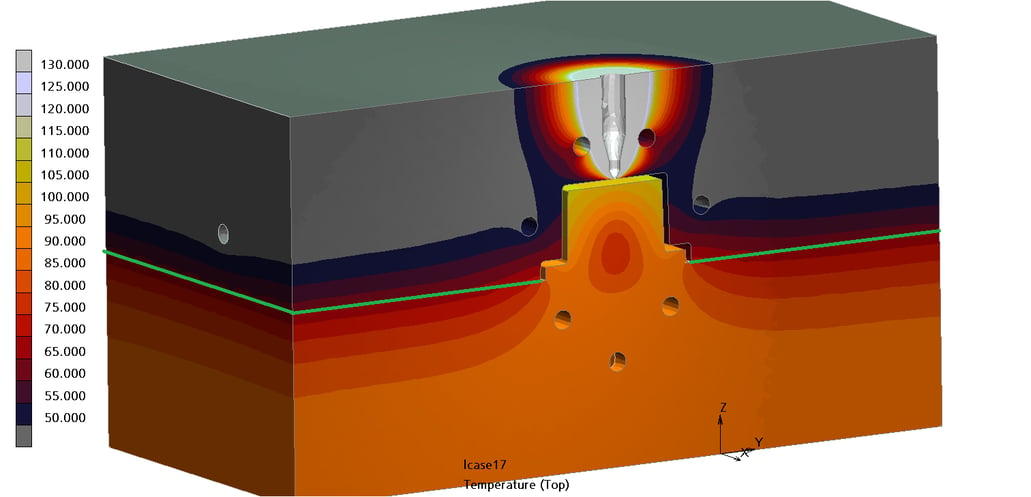

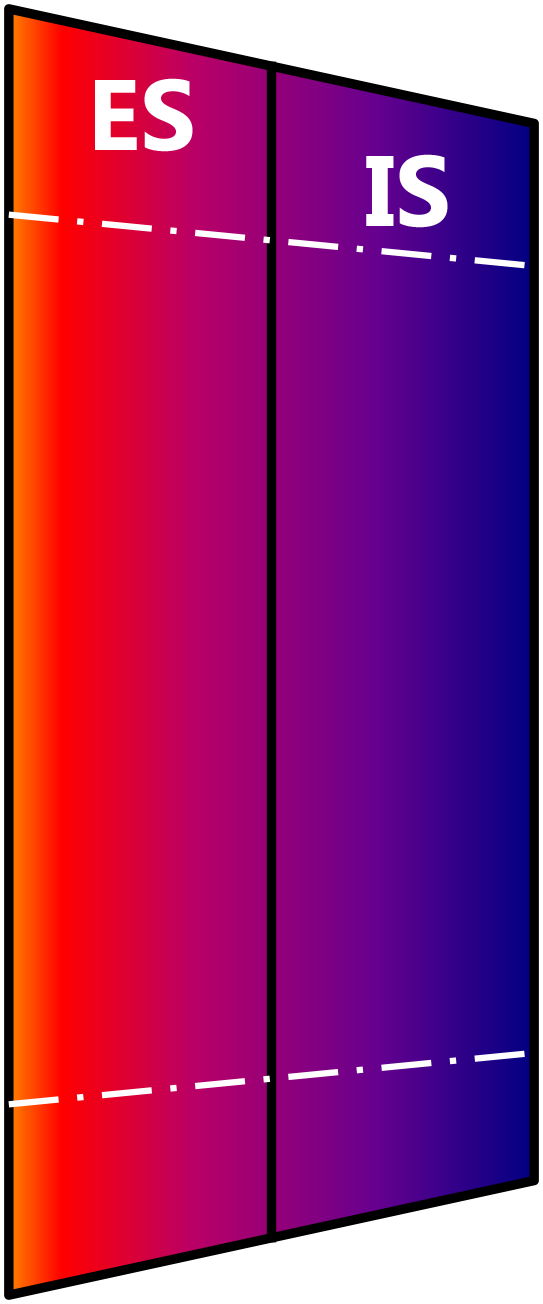

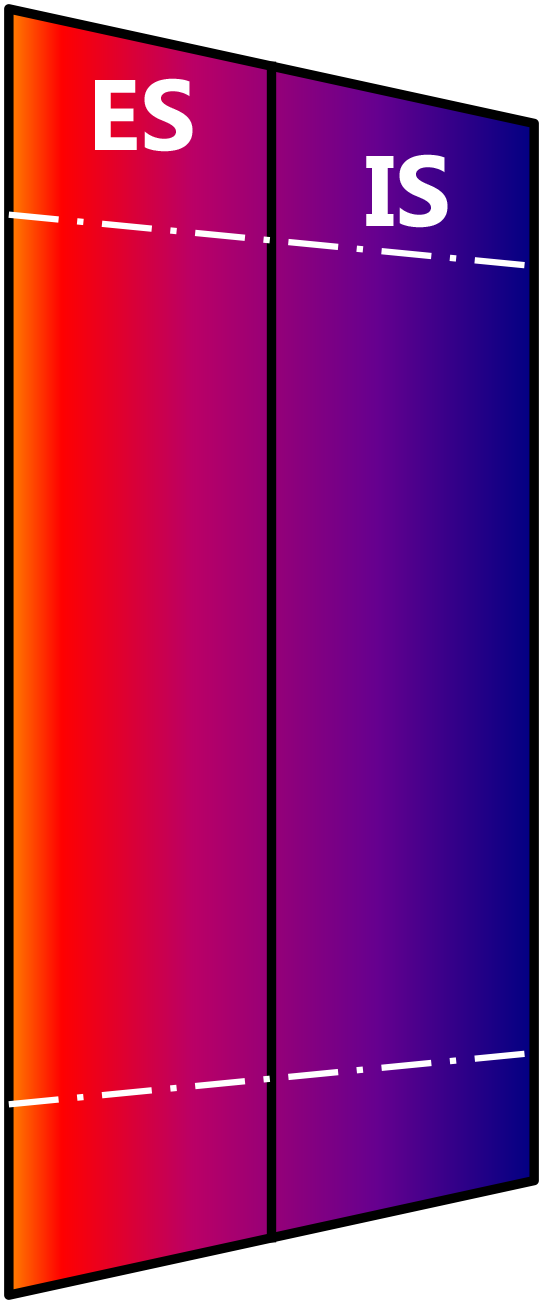

Agathon recently tested this argument. Concretely, Agathon had thermo-mechanical FEM simulations calculated in order to find out; firstly how the heat in the mold was expanded or distributed and secondly to simulate the corresponding influence of thermal expansion on the roller guides. The model used was a simple injection mold with three tempering circuits, one cavity and two built-in Agathon centerings as rolling guide units. These units were installed at a distance of 120 mm from each other and represented in the simulation by rigid, firmly interconnected nodes. In order to simulate the heat influence on the surface of the cavity, a moldflow analysis was performed beforehand. The results of this analysis formed the basis of the FEM simulation. A total of three calculation runs were executed. The following initial values were set:

- Δ 0 °C (32 °F): Injection and ejector sides (IS and ES) were tempered to 70 °C (158 °F)

- Δ 20 °C (68 °F): Injection side tempered to 60 °C (140 °F), ejector side tempered to 80 °C (176 °F)

- Δ 50 °C (122 °F): Injection side tempered to 40 °C (104 °F), ejector side tempered to 90 °C (194 °F)

Figure 1 illustrates the setup of the simulation.

The Agathon centering units performed their work perfectly as long as there was no temperature difference between the two mold halves. But what happened with the other two simulations? Most important result: In the two simulations, in which there was a temperature difference between the injection side and the ejector side, the actually measured offset between the centering pillar and the centering bushing was only one third to one fifth of the calculated theoretical value. As a result, contact between the two mold halves on the contact surfaces resulted in temperature compensation that reduced the temperature difference significantly. This means that there is no temperature jump between ES and IS, but that the temperature at the contact zone changes smoothly from one half to the other.

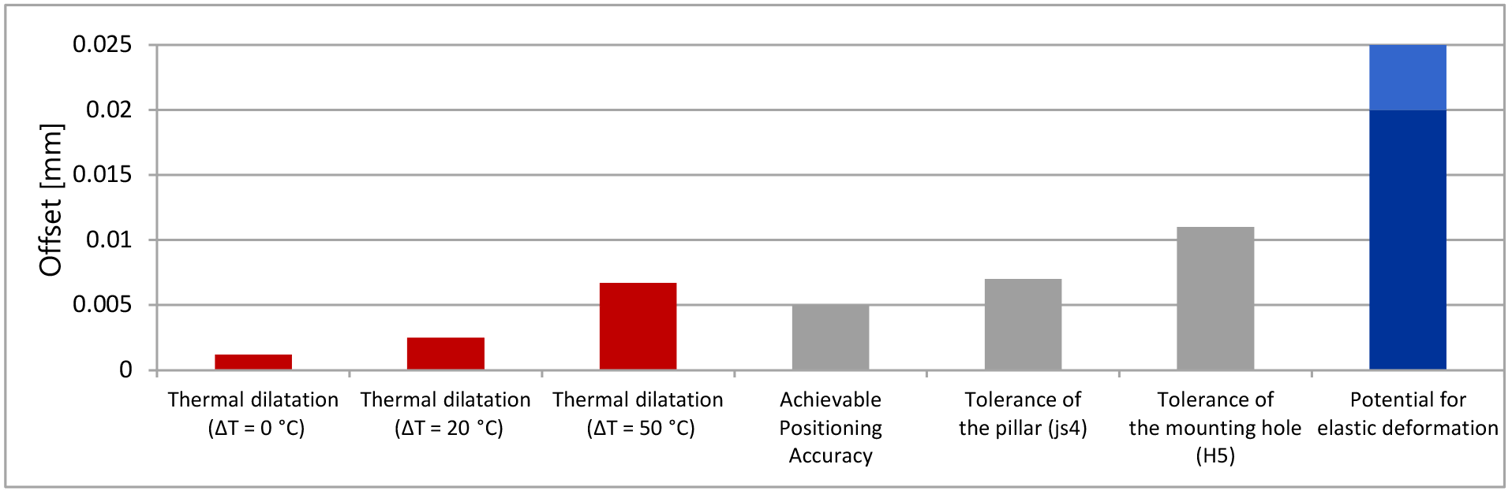

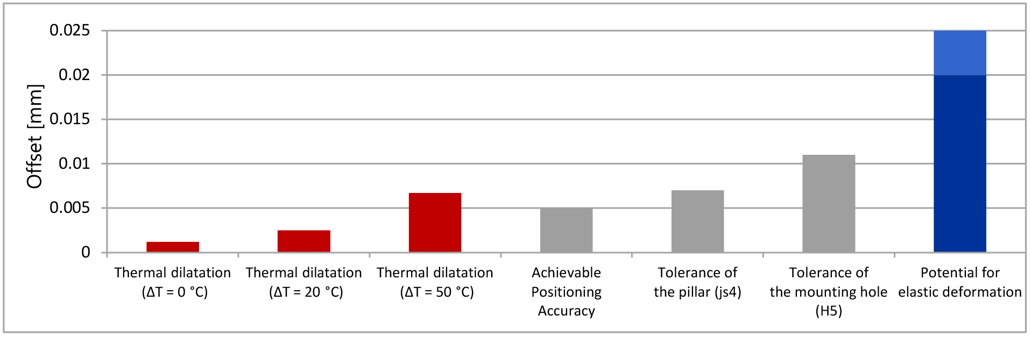

Results from previous simulations and Agathon internal tests show that the (extremely stiff) Agathon centering of the 799X series has the potential to compensate at least two hundredths of a millimeter of misalignment in the event of different thermal expansion. This value is obtained from the elastic deformation of the rolling elements, pillar and bushing and the fitting tolerances of the mounting holes. Figure 3 shows the temperature offsets (red bars), manufacturing tolerances (grey) and the potential for elastic deformation of rolling guides (blue) in relation to each other.

What do these results mean in practice? «Agathon rolling guide elements can also be used without reservations in the mold construction industry», concludes Stefan Nobs. This is particularly true when there are only slight thermal differences in the mold. If higher temperature differences of more than 30 °C are intended in the process, the distance between the guides should be kept as small as possible. And in order to make any effects predictable, it also helps to keep the tool at a uniform temperature. «Of course, we offer all our customers the appropriate support,» explains Nobs, «for example, engineering support, including dimensioning and design of the guiding system.» And so a final question arises: Who still misses the horse-carriage as a standard means of transport today?