To precisely position and close the mold halves of mold making tools, main guiding and centering systems are used. This can now be done particularly efficiently with the standardized Guiding System Plus by Agathon.

Agathon's guiding systems comply with the 6701, 7231 and 8005 series of standards, allowing the mold halves to be guided and centered with just one element. The standard 7231 rolling guide bushing simultaneously takes over the tasks of the main guides and the centering systems. Additional centering systems can thus be dispensed with and the space freed up in new molds can be used for up to 30 percent more cavities. This increases productivity. Depending on the diameter, a clearance-free guide and centering length of 62 to 100 mm can be achieved. This means that even long, delicate components can be demolded gently. The installation dimensions of the system guide correspond to the usual dimensions of conventional guides in mold and die making. Conventional sliding guides can usually be replaced without any adjustments. This makes it easier to replace the previous guides with the innovative guides during normal maintenance. When designing tools, designers can follow familiar design principles but omit the centering systems.

Flexibly applicable

Thanks to the innovative fastening with the freely positionable ring clamp Standard 8005, the combined guiding and centering elements can be used in conjunction with plates of different thicknesses. This is particularly interesting when repairing plates or changing molds. The Norm 7231 roller bush system can be used without pairs, despite the profile rollers used, and can be combined with all columns from Agathon's comprehensive range. Designers can thus design freely and are very flexible. The system guide column 6701 makes it possible to guide stripper plates on the same column. This allows the plates to be guided via pre-tensioned guiding systems._300x200.png?width=300&name=Systemf%C3%BChrung-Plus-(Keine-Artikelnummer)_300x200.png)

Standard simplifies mold design: The Guiding System Plus guides and centers.

Long lifetime

The standard 7231 roller bushings are equipped with heavy-duty rollers. This enables significantly higher travel speeds (up to 40 m/min). Due to the rolling of the rollers, the guides - compared to sliding guides - achieve a five to twelve times longer service life. They operate with high precision over longer periods of time, thus ensuring that components are produced with consistent quality. In addition to immensely increased planning reliability due to significantly less maintenance, product quality and productivity are increased and costs are substantially reduced. The guiding diameters 15, 25, 32 and 40 mm correspond to the installation diameters 30, 42, 54 and 66 mm. With the positioning grooves, the guides can be installed in panels 27 to 116 mm thick, depending on the guide diameter. With Agathon's innovative Guides Plus, only a few standard sizes are needed to build up a wide range of molds. This simplifies and minimizes logistics and inventory. Often, the roller bush system and the system guide column ensure sufficient centering. This even eliminates the need for centering sleeves.

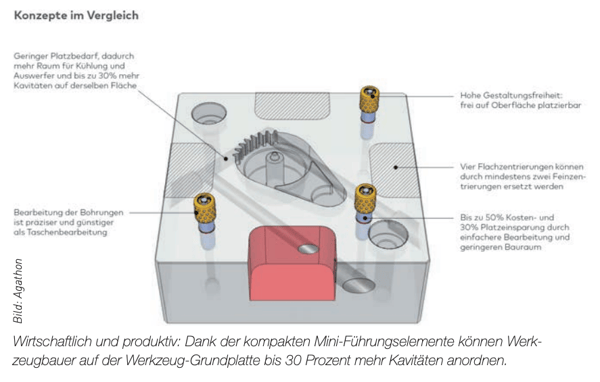

Compact for multicavity molds

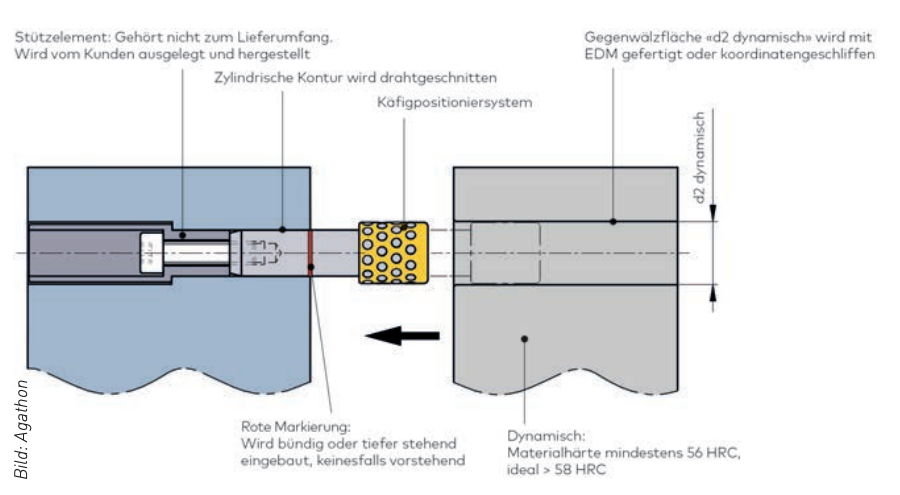

The mini Fine Centering of the 7980/1 standard series, as the smallest centering in Agathon's program, is ideally suited for multi-cavity molds. In the latter, the working surface should have a maximum number of cavities in order to produce productively and economically. The Mini Fine Centering is very compact. This means that cavities can be arranged on the mold plates in an area of just 60 x 60 mm. If required, the fine centering can even be installed without a bushing.

The moldmaker manufactures the counter-rolling surface himself. By design, up to 30 percent more cavities can be arranged in the mold. At least two centerings must be provided in a mold. Four are usual, but a larger number can also be installed. The fine centerings are backlash-free thanks to preloaded rolling elements. They therefore center and guide more accurately than sliding guides. They are also wear-free and have a much longer service life. It is sufficient to relubricate weekly or less frequently with minimal quantities.

Compact: For precise guiding, holes made by the toolmaker's shop in the base plates serve as a counter-rolling surface for the rolling guiding bush.

This article has been published in German in SMM Schweizer MaschinenMarkt and on maschinenmarkt.ch, the leading and widest-reach trade media (print and online) for manufacturing technology and automation in Switzerland. The pictures are therefore original according to the publication.