Leo Peri - low cost per workpiece

Maximum productivity in a small space

Leo Peri - perfect options

Leo Peri - High-precision 4-axis grinding center for machining the periphery of indexable inserts

Compact design

with excellent accessibility and rooftop

mounting for peripherals

Compatibility

Tools, operation and programming are largely compatible with the other Agathon machines

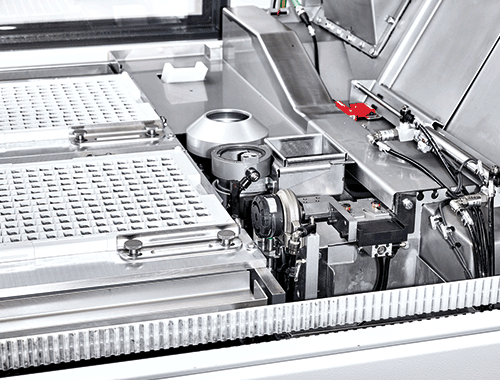

Fully enclosed grinding area

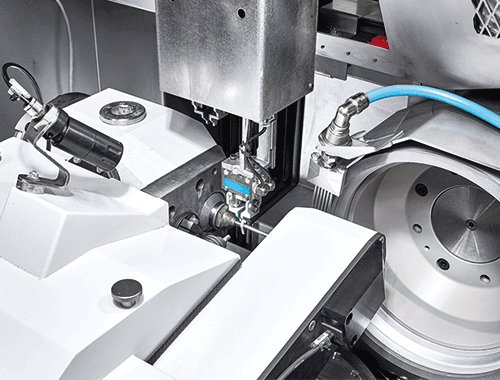

Very compact Grinding area with grinding wheel diameter 250 mm and direct drives with optimized performance for the X, Y and C axes.

Low-maintenance drives

easy to maintain due to excellent accessibility

State of the art technology.

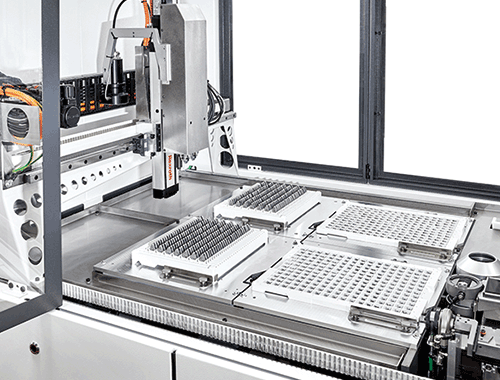

Handling

Dynamic, fully integrated 3-axis linear handling

The Leo Peri concept

Leo Peri - basic machine

● Dynamic, fully integrated 3-axis linear handling

● Support for 4 up to 6 pallets

● Direct drives with optimized performance for the X, Y and C axes

● In-process dressing suitable for grinding a wide range of materials

● Compact, fully enclosed grinding area

● Grinding wheel diameter 250 mm

● Tools, operation and programming are largely compatible with the other Agathon machines

Technical data

|

Number of paletts

|

4 bis 6

|

|

Grinding cup Ø

|

250 mm / 280 mm

|

|

Dimensions (L x W x H)

|

2.98m (3.80m) x 1.29m (2.88m) x 2.11m (with lamp 2.52 m)

|

|

Working height

|

950 mm

|

|

Weight

|

3100 kg

|

|

Swiveling range of C axis

|

-45° (-75°) bis + 36°

|

|

OD | IC

|

max. 35 mm | min. 3.96 mm

|

|

Workpiece – Clamping dist.

|

max. 15 mm

|

|

Materials

|

Carbide, Cermet, Ceramics, CBN, PCD

|

Ease of use

● Consistent Agathon operating philosophy and software

● Unique, domain-specific programming language for indexable inserts

● Optional software for easy creation of programs for ISO indexable inserts (AGP-Iso)

● Simple re-teach

● Easy to clean due to a compact, fully enclosed grinding area

● Easy to maintain due to excellent accessibility

● Comprehensive training program for programming, operation and maintenance

Selected options

● Chamfer grinding of simple ISO inserts with a K-Land of more than 15°

● Graphical creation of programs for ISO indexable inserts (AGP-Iso)

● 2D force measurement system for normal and tangential forces for the process definition, optimization and control

● Vision system for parts alignment and spot recognition

● Extensive possibilities for Connectivity and Data Management

The outstanding advantages of the Leo Peri

Highest productivity per m2

● Access required from 3 sides only; alternative machine installations (flush against wall, back to back)

● Prepared for rooftop mounting of all peripherals

● Full possibilities to integrate fire extinguishing system

● All connections of the machine are centralized

Low cost per workpiece

● Short transfers due to agile handling and in-process dressing

● Standardized, compatible Agathon tools

● Fast product change due to off-line programming and graphic simulation

● Reduced energy requirements through consistent Eco-design

● Low-maintenance components

Maximum availability

● Short changeover/set-up times

● Designed and manufactured in Switzerland

● Fast, competent and efficient teleservice and on-site field service