Unmatched flexibility in one clamping

Extended travel ranges and swivel angles without re-clamping

Perfect options - e.g. PowerGrind (electro-erosion conditioning process)

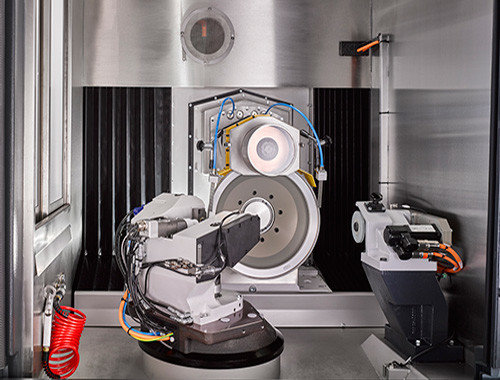

Evo Combi - 4-axis grinding center for machining the periphery and 2 K-Lands in a single clamping

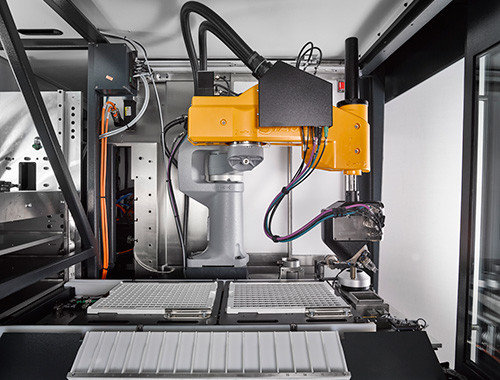

Handling

● Agile SCARA Handling

● Two pallets in the work area for separation of blank and finished parts

Compatibility

● Standardized, compatible Agathon tools

● Consistent Agathon operating philosophy and software

● Unique, domain-specific programming language for indexable inserts

Optimized Drives

● Extended travel ranges and swivel angles for the production of indexable inserts without re-clamping

● Fast, enduring B-axis, optimal for round inserts

● Direct drives with optimized performance for the X, Y and C axes

● Internal and external dressing devices can be combined

● Grinding wheel diameter 400 mm

Connectivity

Extensive possibilities for Connectivity and Data Management.

The Evo Combi concept

Evo Combi - basic machine

- Proven design with good accessibility

- Extended travel ranges and swivel angles for the production of indexable inserts without re-clamping

- Fast, enduring B-axis, optimal for round inserts

- Direct drives with optimized performance for the X, Y and C axes

- Internal and external dressing devices can be combined

- Grinding wheel diameter 400 mm

- Grinding area separated from handling area

- Two pallets in the work area for separation of blank and finished parts

Technical Data

| Number of pallets | max. 16 |

| Grinding cup Ø | 400 mm |

| Dimensions (L x W x H) | 3.06m x 2.10m x 2.22m (with lamp 2.60m) |

| Weight | 6500 kg |

| Swiveling range of C axis | -140° bis +140° |

| OD | IC | max. 100mm (120mm) | min. 3.96mm |

| Workpiece – Clamping dist. | 28.5mm |

| Materials | Carbide, Cermet, Ceramics, CBN, PCD |

Ease of use

- Excellent visibility

- Workpiece spindle head close to machine front for better access

- Consistent Agathon operating philosophy and software

- Unique, domain-specific programming language for indexable inserts

- Simple re-teach

- Proven, perfectly integrated automation

- Comprehensive training program for programming, operation and maintenance

Selected Options

- Electro-erosion conditioning process (PowerGrind)

- Robust U-axis for in-process cleaning, sharpening and profiling

- 2D force measurement system for normal and tangential forces for the process definition, optimization and control

- Extensive possibilities for Connectivity and Data Management

- Vision system for parts alignment and spot recognition

The outstanding advantages of the Evo Combi

Low cost per workpiece

- Shorter grinding times thanks to very high material removal rates

- Short transfers due to agile handling and internal dressing

- Complete machining without re-clamping

- Standardized, compatible Agathon tools

- Fast product change due to off-line programming and graphic simulation

- Up to 50% cycle time reduction with PowerGrind

- Low-maintenance components

Flexibility (materials, process)

- K-Lands on both sides without re-clamping

- Extended swivel angles and travel ranges for significantly more geometries

- Free combination of various dressing methods

- Largest possible range of applications from IC 3.96 mm to OD 100 mm

- Suited for all common indexable insert materials

- Reduced energy requirements through consistent Eco-design

Maximum availability

- High autonomy with storage for up to 16 trays

- State-of-the-art, low-maintenance drives

- Short changeover/set-up times

- Designed and manufactured in Switzerland

- Fast, competent and efficient